Missouri Protoplex

The Missouri Protoplex is a reflection of the statewide ecosystem of manufacturing and technology it serves, the Missouri Protoplex is conceived as a place where industry and academia come together to research new materials and methods, prototype and test new manufacturing processes, develop workforce competencies, and solve multi-discipline problems required to bring integrated cyber-physical manufacturing systems into practical use.

Executive Summary

Missouri Protoplex Guiding Principles

- As the cornerstone of a new applied research campus, Protoplex will be the manufacturing innovation hub for the State of Missouri.

- Through shared facilities and equipment, Protoplex will provide new pathways for innovation in solving advanced manufacturing challenges.

- Protoplex will be a welcoming, inspiring facility where the University, its industry partners, and citizens can see advanced manufacturing processes being developed and tested.

- Protoplex will promote entrepreneurship and the economic development of industries within the state and region, enhance workforce competencies, and significantly aid in growing the gross domestic product in manufacturing.

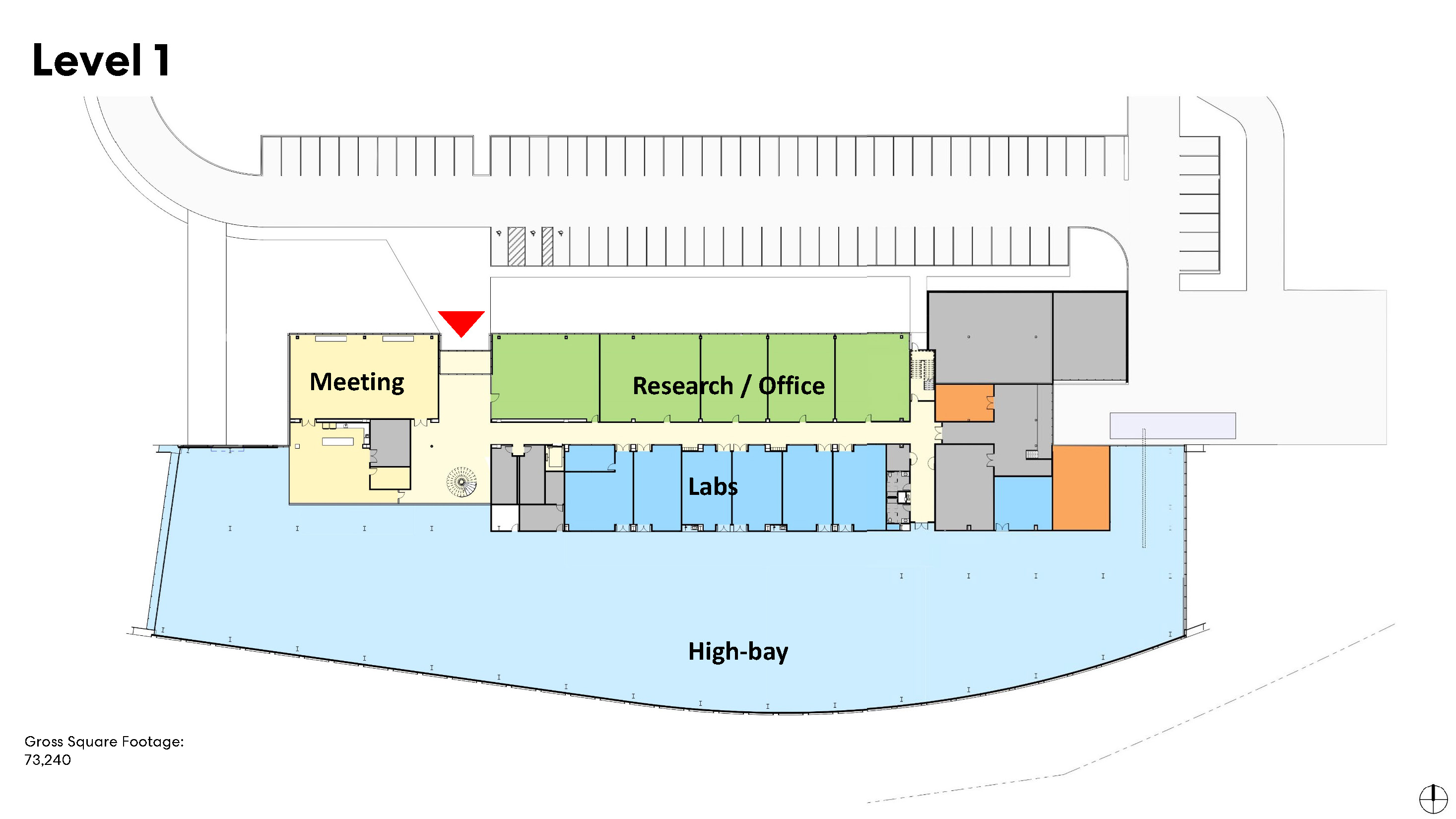

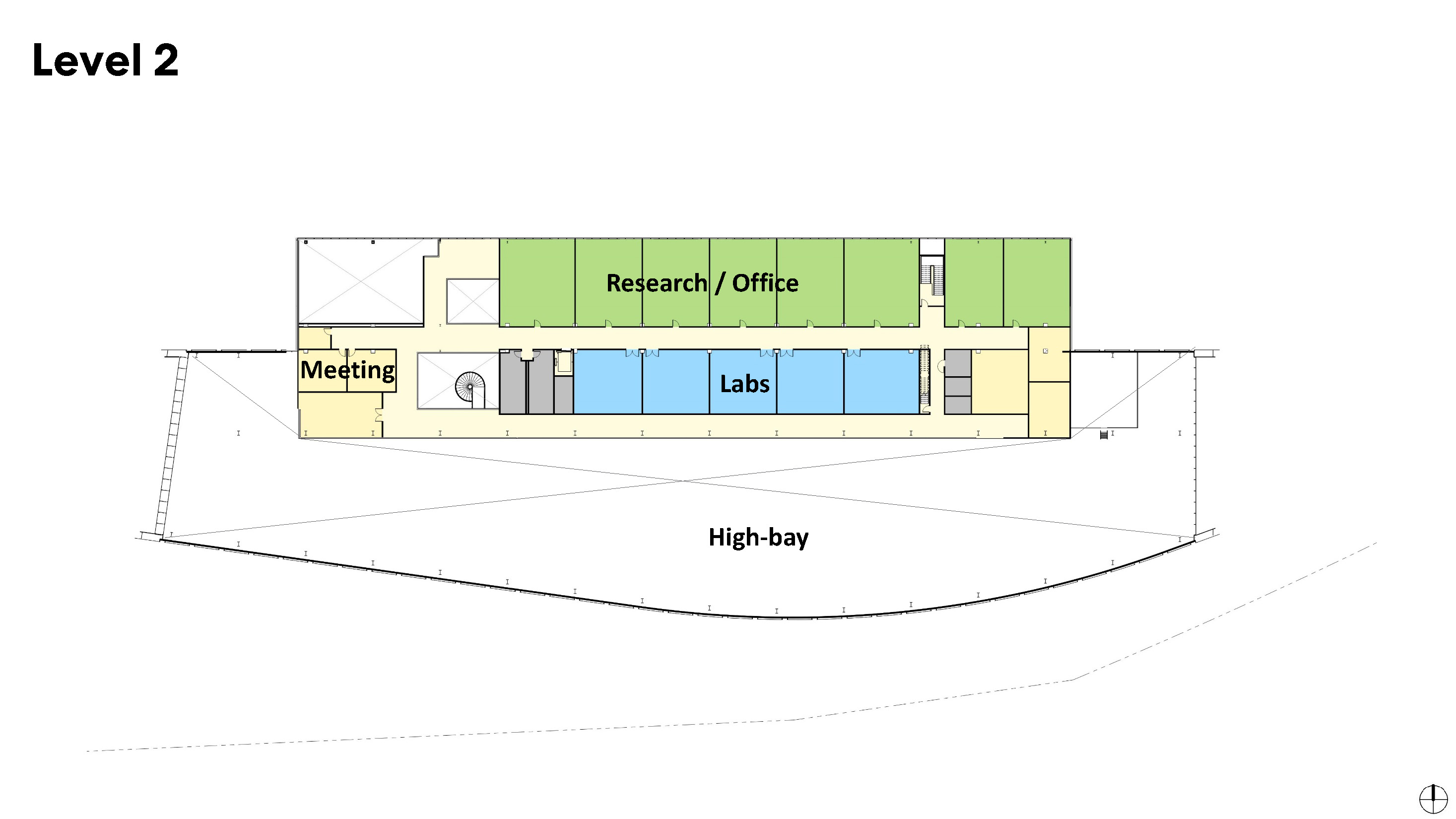

The collaborative work for which this new facility is intended and requires flexibility to move back and forth between suites of traditional lab, office, and conference spaces, and large, secure, well-appointed high-bay manufacturing lab spaces. Placing these dual work environments adjacent to one another in each discipline will allow fluidity of movement required for rapid prototyping, as well as visual transparency, to improve communication, coordination of the work, and safety for all occupants. The new facility is organized around the four fundamental disciplines of the manufacturing ecosystem itself.

- Materials, Manufacturing & Methods

- Pre-Production Testing & Development

- The Forge–Steel and Advanced Metallurgy

- Cyber-Physical Systems Security, Testing & Development

Each of these individual discipline areas is characterized by and will be designed around current and evolving needs for both space and equipment in both the office/lab suites and high-bay research and production facilities, with loose-fit flexibility to accommodate the continual evolution of the work, the technology, and the relationships. To maximize interdisciplinary collaboration and facilitate communication required to leverage ideas from prototype to production, the building arranges these four discipline areas around a bright, open, and energetic central core of shared circulation, conference, and amenity spaces. Ample glazing on the interior and exterior of all levels allows the new facility to communicate both its purpose and its processes.

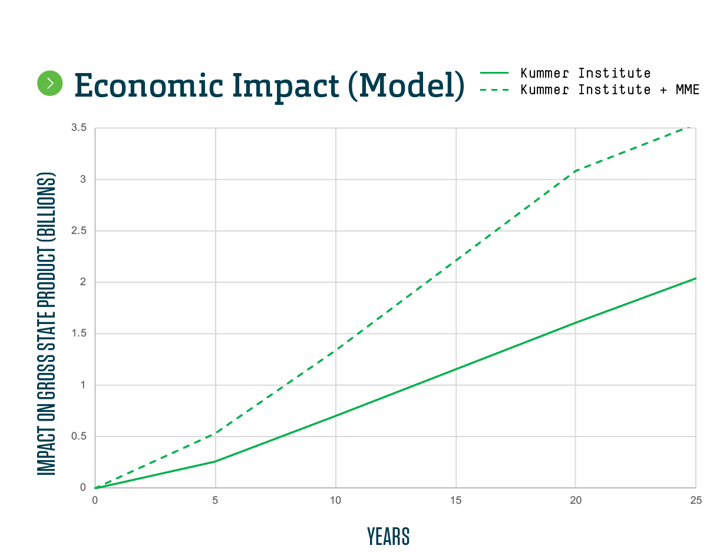

Economic Impact

A $300 million gift from benefactors June and Fred Kummer established the Kummer Institute (KI) at Missouri S&T. The KI is positioning S&T as a national leader in innovation and entrepreneurship, and will bring economic prosperity to south-central Missouri. According to an economic impact study by Dr. Joseph Haslag, a professor of economics at the University of Missouri-Columbia, a $100 million investment, on top of the Kummer investment, is projected to yield $3.5 billion in gross state product over 35 years.

Materials, Manufacturing & Methods

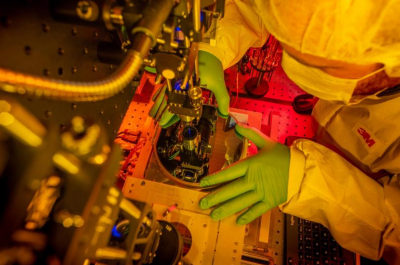

Create innovative materials and resolve complex fabrication problems using:

- Computer modeling

- Materials science

- High-technology fabrication equipment

Pre-Production Testing & Development

Companies will work with S&T experts to improve functioning, precision and efficiency of existing automated manufacturing equipment. Expertise areas:

- Mechanical engineering

- Manufacturing engineering

- Robotics

The Forge–Steel and Advanced Metallurgy

S&T engineers and scientists will explore new methods to rapidly create and test alloys to expand manufacturer's toolkit of available materials for:

- Structural applications

- Industrial applications

- Aerospace applications

Cyber-Physical Systems Security, Testing & Development

Essential to Industry 4.0

- Software, wireless communications and hardware experts

- Need lab space to continually innovate, test and refine new automation systems and controls

- Need lab space to investigate, solve discreet problems for manufacturers using cyber-physical systems

Innovation and Entrepreneurial Thinking

A recent survey of Missouri S&T graduates indicates that the vast majority of students are going on to established companies upon graduation, showing little interest in smaller start-up companies. This is a key indicator that the campus lacks a culture of innovation and entrepreneurial thinking critical for a science and technology-focused institution. The purpose behind Missouri S&T’s new Missouri Protoplex Facility is to create a dynamic, campus-wide culture of innovation and entrepreneurialism. This new facility will be a place to forge and explore partnerships between academic research, entrepreneurial start-ups, and established companies. Additionally, the types of research spaces envisioned will support Missouri S&T’s goal of achieving the more research-intensive Carnegie R1 classification.

A recent survey of Missouri S&T graduates indicates that the vast majority of students are going on to established companies upon graduation, showing little interest in smaller start-up companies. This is a key indicator that the campus lacks a culture of innovation and entrepreneurial thinking critical for a science and technology-focused institution. The purpose behind Missouri S&T’s new Missouri Protoplex Facility is to create a dynamic, campus-wide culture of innovation and entrepreneurialism. This new facility will be a place to forge and explore partnerships between academic research, entrepreneurial start-ups, and established companies. Additionally, the types of research spaces envisioned will support Missouri S&T’s goal of achieving the more research-intensive Carnegie R1 classification.

Goals include a facility to explore a place to manufacture an active environment not a place for startups but to partner with companies and government entities who want to avoid the issues with “Tech Park '' and having too many offices with an emphasis on being an incubator. New facilities should be able to move through to pre-manufacturing stages Like the current high bay spaces on campus, but a much larger location is connected to the main campus, but it is separated by being a creative working and professional environment industry involvement plugs into the facility but does not drive the facility.

Architect Review and Recommendation Committee

- David Borrok (Co-Chair) / Dean, College of Engineering and Computing

- Richard Billo (Co-Chair) / Director, Kummer Institute Center for Advanced Manufacturing & Protoplex Director

- Douglas Bristow / Professor of Mechanical Engineering

- Mike Moats / Department Chair and Professor, Materials Science & Engineering

- David Bayless / Chair and Professor, Mechanical & Aerospace Engineering

- Fred Stone / Associate Vice Chancellor of Facilities Planning and Operations

- Kamal Khayat / Vice Chancellor Research & Innovation, Professor & Vernon Maralee Jones Chair, Civil Engineering

- Joseph Newkirk, Department Chair & Professor, Nuclear Engineering & Radiation Science

Program Study By: Mackey Mitchell Architects